diy injection molding machine plans

DIY Injection Molding How to Get Started Step 1 Get frames to make the mold. There are specific cooling times for different parts and components depending on the maximum.

Plastic Injection Moulding Machine Model 4 Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

Got it cheap of.

. The lip around the. Request A Quote Today. Threads would essentially be treated as undercuts by the injection molding machine and that adds significant cost to the entire process.

The Complete Guide to DIY Molding Resin Casting. Injection Molding SIZING AN INJECTION MOLDING MACHINE Packing pressure 108Pa Clamping force F PA Figure 7. Well use the open-source Blender but the workflow should be fairly similar in any other CAD software.

First pick the CAD software tool of your preference to design the mold insert. Step 3 Pour in. The first step in our injection molding setup is to create a mold.

At this stage raw plastic material or pellets are fed into the injection molding machine pushed into the injection unit melted and then injected into the mold. Hence designing parts with a thread on it is not recommended. Browse Our Catalog Of 3000 Quality Products With Many Available For Quick Shipping.

Adding threads to injection molded parts can become quite tricky especially if the threading is included in the designing phase of the part itself. Then I was able to make copies of that item using a home plastic injection molding machineThis process should work for many different types of items or models. I made an epoxy mold of an existing plastic item.

We have attempted to answer that question for you by providing these plans for a small hobby size injection molding machine capable of molding slightly more than 12 ounce of plastic. Beyond that at right are typical prices for other auxiliary. Mods include the plungerpull handle plunger guide heater block and temperature controller.

Cooling allows the molten plastic to solidify and take the shape of the mold. The wider block allowed me to add a second cartridge heater B so my machine warms up quicker and can get hotter. I used a leftover piece of 12 hot rolled steel instead.

Adding threads to injection molded parts can become quite tricky especially if the threading is included in the designing phase of the part itself. Ad Over 70 New. Injection molding auxiliary equipment.

DIY Injection Molds With Dremel CNC And Hot Glue 2 Plastic Injection Moulding Machine - model 4 Small injection molding machine Making molds for the Buster Beagle 3D Injection Molding Machine Automatic Unscrew Thread Injection Mold. Aluminum is usually good for 8000pcs and EDM carbon steel can handle over 50000pcs. Find Injection Molding Machine Plans now.

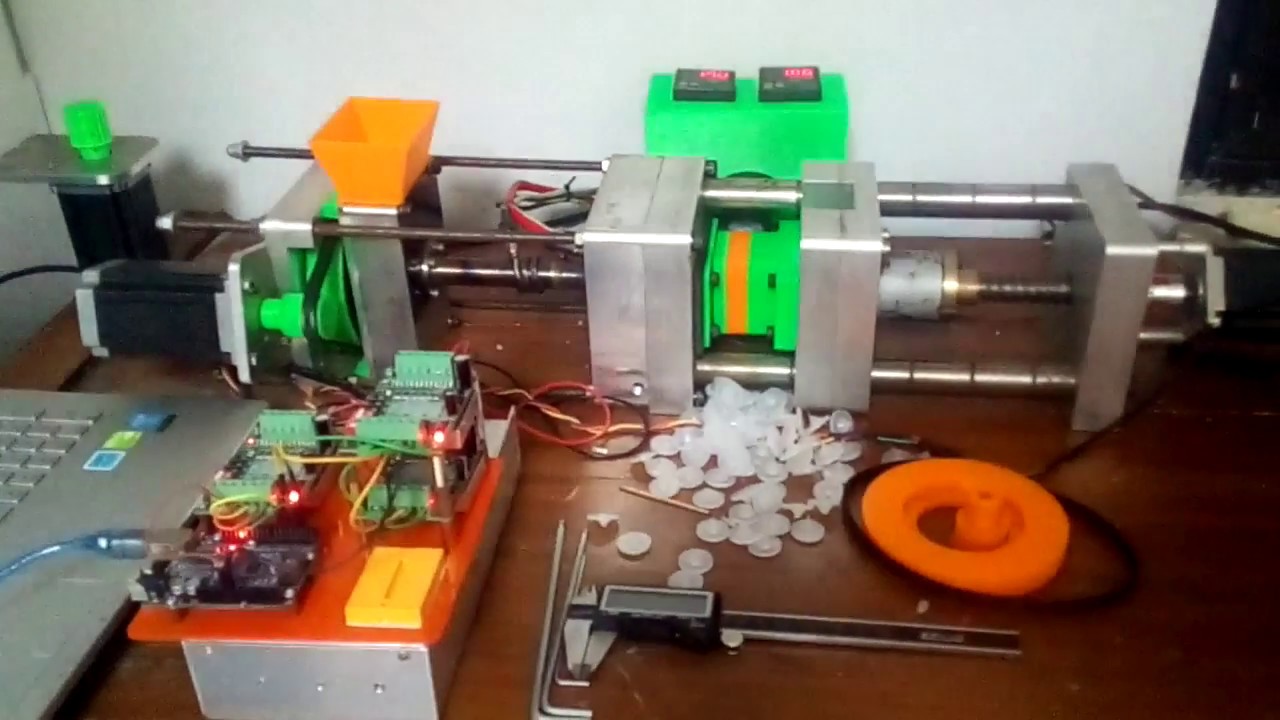

Machine is driven by two air cylindersMaterial used for test is BASF Elastollan TPU regrind. That article continues to capture eyeballs getting as manyand sometimes morepage views than current content. Design the Mold in CAD.

DIY Injection Molding Press. The central material dryinghandling system including five insulated drying hoppers dehumidifying dryer pumps filters and conveying system would cost about 115000. In recent years the use of CNC has been increasingly adopted in injection molding machines giving rise to the popularity of models that enable.

Talk To Employee Owners For Your Custom Injection Molding Needs. Injection molding machine is divided into 2 units ie. Frame was constructed from scrap metal.

Make Your Own Injection Molding Machine Make Plastic Injection Molding Diy Molding Plastic Injection All that you need is a heater and some plastic. Do you ever want to. The structure of an injection molding machine can be briefly summarized as consisting of an injection unit that sends the melted materials into the mold and a clamping unit that operates the mold.

Epoxy composite injection molds require no machining and are good for 800 pieces. Do you ever need spare plastic parts or need to replace a broken or worn part such as a plastic cap or a door bell switch. About seven years ago PlasticsToday published an article about a tabletop injection molding machine the 20A PIM-Shooter developed by LNS Technologies Scotts Valley CA.

Mold a single tensile bar - 50 ton machine Mold a front end of a car - 5000 ton machine Typical sizes are 100-1000 tons For complicated parts A. The functions of the clamping unit are opening and closing a die and the ejection of products. Injection molding machine and Equipment prices.

Test of DIY plastic injection molding machine. Ad Premium Casters Levelers Glides Tubing Hardware Manufacturer. While 3D printing has now become easily accessible and cheap there are still several use cases where you need the advantages offered by injection molding even for.

Once you have your frames in place proceed with setting up the frames for. The designs can also be easily. Find Injection Molding Machine Plans now.

This is the new ebay. Given the enduring interest in this piece of equipment we thought it. 59 ounce to be exact This amazingly compact machine is designed to be used with a floor model style drill press having a minimum spindle travel of 3 inches.

Homemade plastic injection molding machine based on the Gingery design. There are 2 types of clamping methods namely the toggle type shown in the figure below and the straight-hydraulic type in which a mold is directly opened and closed with a hydraulic cylinder. Home Plastic Injection Molding With an Epoxy Mold.

A clamping unit and an injection unit. Step 2 Setup the modelitem in the mold. The plans call for a 11½4 piece of cold rolled steel for the heater block A where the plastic is heated before being injected into the mold.

Clamping force as a function of surface area. Download the blank mold insert design filesyoull use them to create your injection mold design. Ad Our Talented Diverse Skilled Experts Make Injection Molding More Economical Efficient.

DIY Injection Molding Step by Step 1.

Home Injection Molding Plastic Injection Molding Injection Moulding Plastic Moulding

Solidworks Hydraulic Injection Molding Machine Injection Machine Injection Moulding Plastic Injection Molding

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Manual Plastic Injection Molding Machine Plans Ebay Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

Make Your Own Injection Molding Machine Make Diy Molding Plastic Injection Molding Homemade Machine

Manual Benchtop Injection Molding Machine Mim 100 A Standard Mold Free Shipping Business Indu Plastic Injection Molding Injection Machine Plastic Injection

Homemade Plastic Injection Molding Machine Plastic Moulding Plastic Injection Moulding Machine Diy Molding

Electronics Cars Fashion Collectibles Coupons And More Plastic Injection Molding Diy Molding Plastic Injection Moulding Machine

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Mould Design Injection Moulding

Micro Molding Materials Market Plastic Raw Material Molding Plastic Injection Molding

Manual Benchtop Injection Molding Machine Model 150a Pim Shooter Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

Homemade Plastic Injection Molding Machine Pdf Ftempo Inspiration Plastic Injection Molding Plastic Injection Temperature Control

Injection Molding Machine By Scorch Homemade Plastic Injection Molding Machin Plastic Injection Moulding Machine Plastic Injection Molding Plastic Injection

Diy Injection Molding Machine Plastic Injection Molding Plastic Injection Moulding Machine Plastic Injection

Desktop Injection Molding Machine Get Inquiries 56 Youtube Plastic Injection Molding Injection Machine Plastic Moulding

Pin By Arbi Oussama On Car Lights Plastic Injection Molding Plastic Injection Moulding Machine Plastic Moulding

Make Your Own Injection Molding Machine Make Mold Making Metal Working Projects Plastic Injection Molding